BUILT TO PASS, BUILT TO LAST.

QUALITY

ASSURANCE

PREMIUM QUALITY

From Start to Finish, Quality in Every Phase.

At Mengtex, quality is our top priority. We follow a strict 3-phase quality assurance process—Pre-Production, Production, and Post-Production—to ensure every package meets the highest standards. We begin by confirming all design and material details and creating a sample proof. During production, we use advanced color management and monitor material quality closely. Finally, our expert QC team conducts a thorough inspection before the packaging reaches you, guaranteeing reliability and excellence.

PHASE 1:

Pre-Production

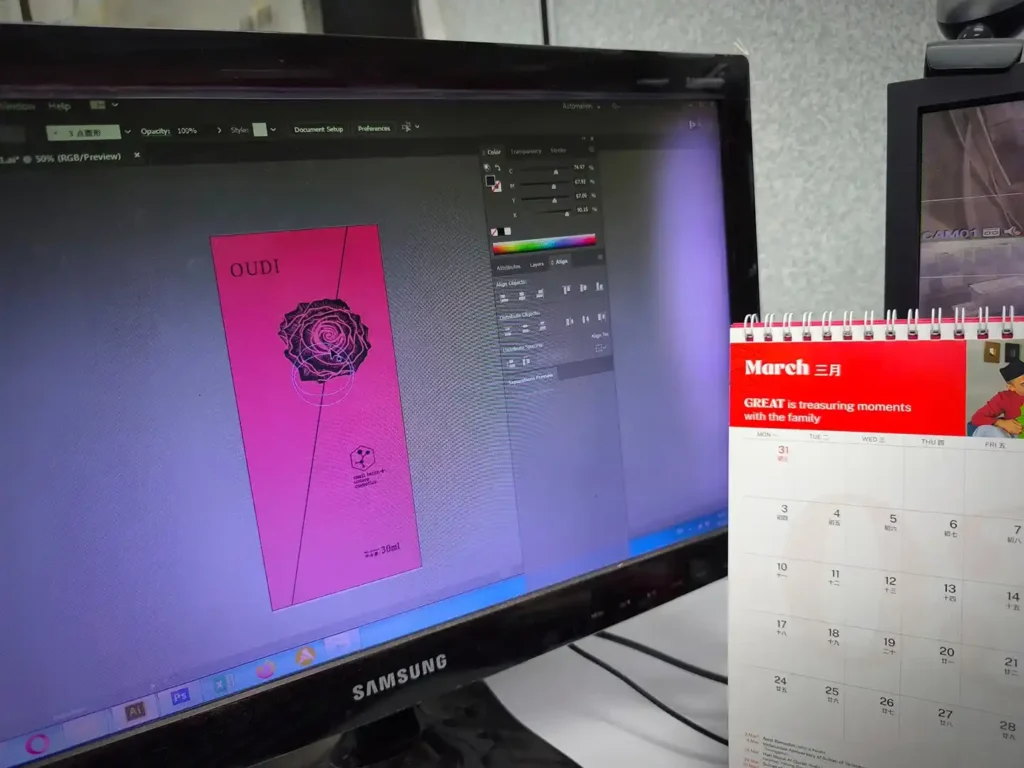

Artwork (Design)

Confirmation

At Mengtex, we will perform artwork checking process before production. Our team reviews every file to ensure it meets the highest standards—this includes verifying image resolution (DPI) for crisp, clear prints, checking colors for accuracy and consistency across different media, and reviewing text for any grammatical errors or typos. We also assess layout alignment, bleed settings, and file formats to prevent any issues during printing. This careful inspection process helps us deliver flawless results and ensures your final product looks exactly as intended.

Structure (Size)

Confirmation

To ensure diecut precision and top-tier quality, we rigorously verify the structure and dimensions of every design before production. A diecut sample is also created using a sample plotter cutter for customer to confirm size accuracy. Whether it’s packaging, labels, or custom shapes, we will ensure each file aligns precisely with diecut specifications—preventing misalignment and trimming issues. We also confirm that the product fits perfectly within the packaging dimensions, avoiding fitting problems and ensuring a smooth packaging process. With a curated book of over 500 diecut templates, our clients can easily select the ideal structure option for their project, saving time and achieving a perfect packaging every time.

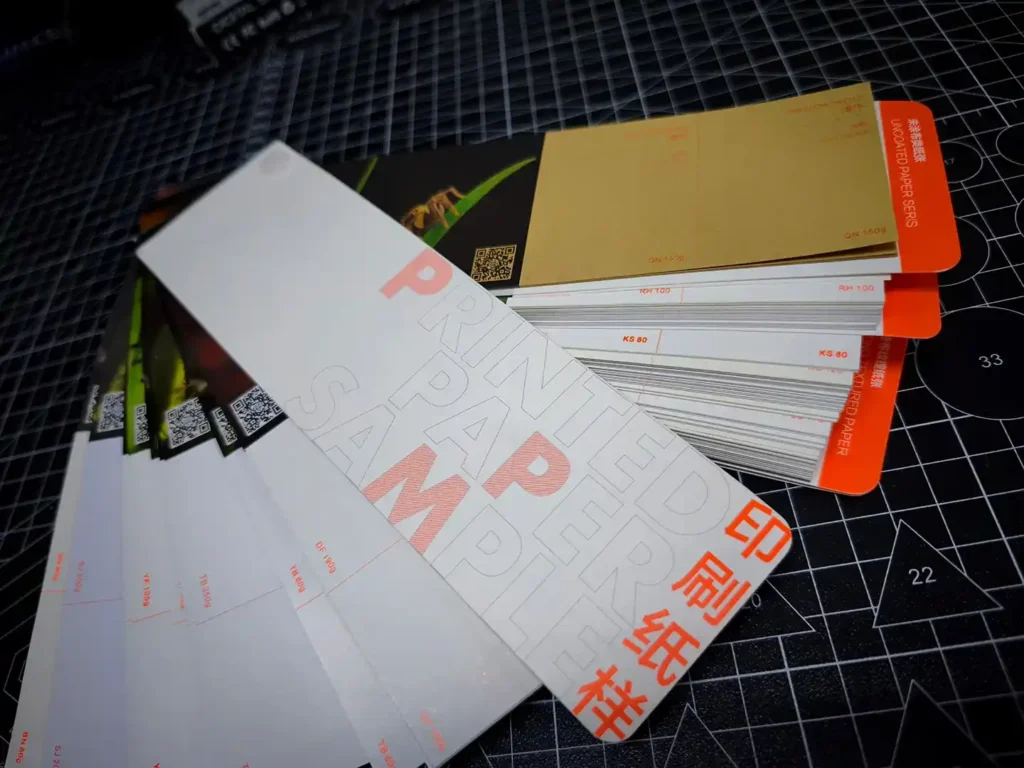

Material

Confirmation

For material confirmation, we provide an extensive sample book showcasing every type of paper and board—allowing customers to see the printed effect and physically feel the texture, thickness, and smoothness. From simili, art paper, art card, boxboard, kraft paper, to ivory card and other specialty papers, our collection covers a wide range of options in various GSM weights. Clients can also compare the differences between coated (1-side or 2-side) and uncoated materials to find the most suitable choice for their project’s look and feel. This hands-on approach ensures full confidence in material selection before production begins.

Value Added Method

Confirmation

To help our customers confidently select the perfect finishing touch, we offer a comprehensive Value Added Method Confirmation process. With our exclusive mobile app, sample books, and a wide range of physical product examples, clients can see and feel the effects of each value-added option before making their final choice. Our collection showcases real-world applications, helping customers visualize the impact on their own designs. We proudly offer the most advanced value-added service in the world, combining technology, craftsmanship, and innovation to elevate every project to a premium level.

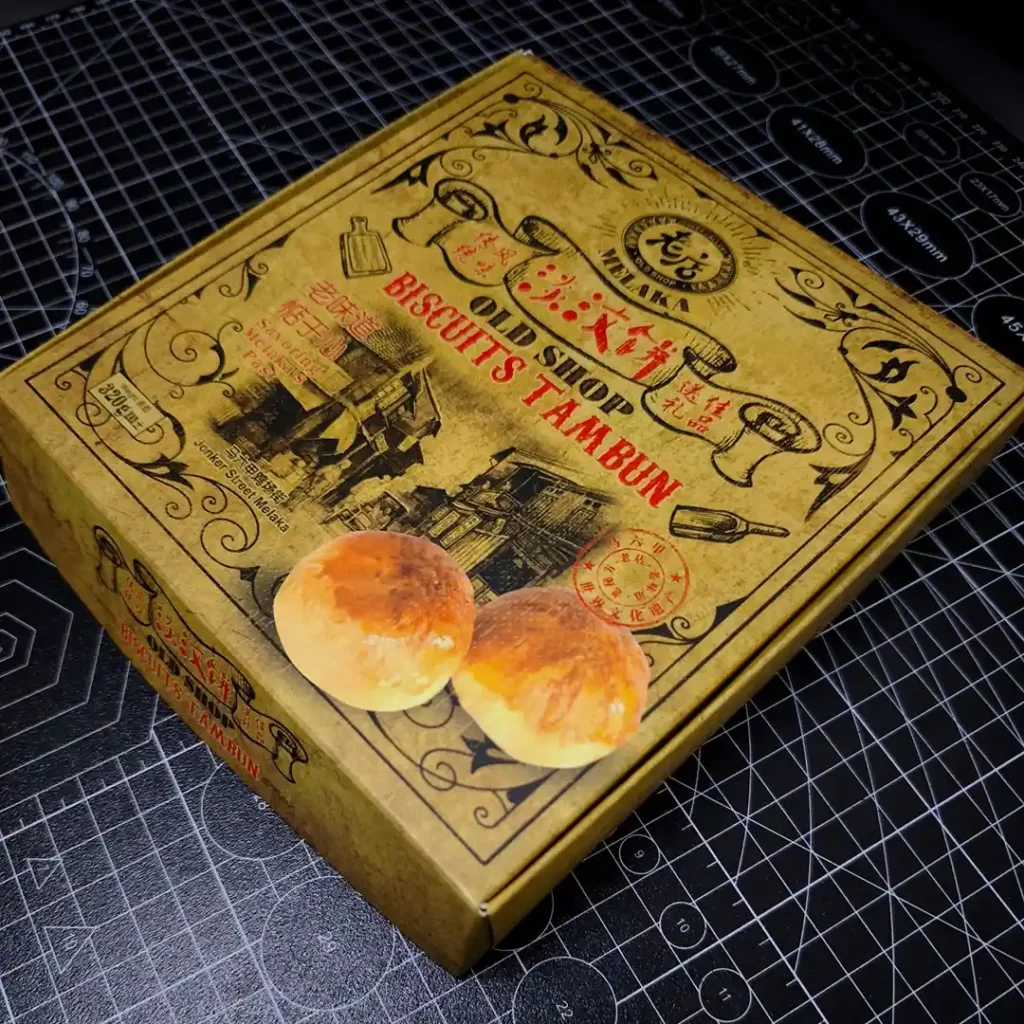

Sample Proofing

To give our clients full confidence before mass production, we offer sample proofing using actual prints and diecut. This allows you to see and feel exactly how the finished product will look like—ensuring color accuracy, material quality, and precise finishing. We also include every value-added services such as embossing, foil stamping, or spot UV in the sample, so you can evaluate every detail firsthand. This hands-on proofing process minimizes risk, streamlines approval, and guarantees a result that meets your expectations.

PHASE 2:

Production Stage

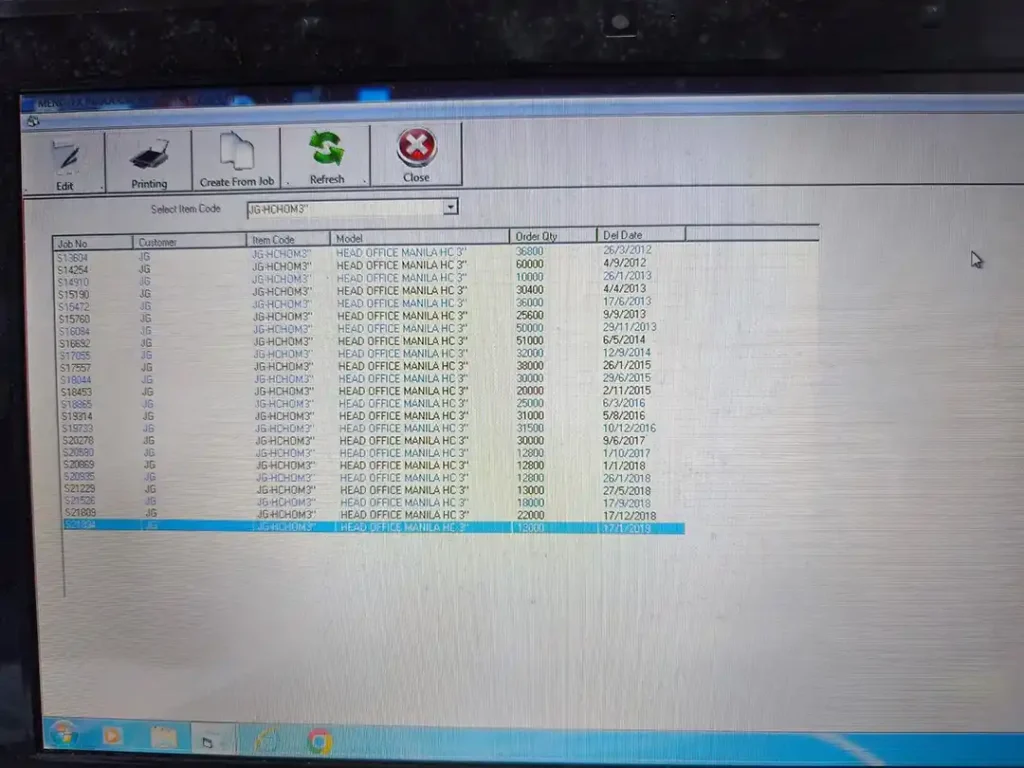

Custom Built Production Software

Our custom-built production software ensures accuracy at every stage of the production . The responsible team member of each section must sign and record key details such as material used, paper waste, quantity completed, and any issues encountered into the system during production. This system also stores all job information—including specifications, materials, and precautions making customer easy to repeat their order and also our team to redoing the job consistently and efficiently. It also help in real-time status tracking, giving our team clear visibility into the progress of each order from start to finish.

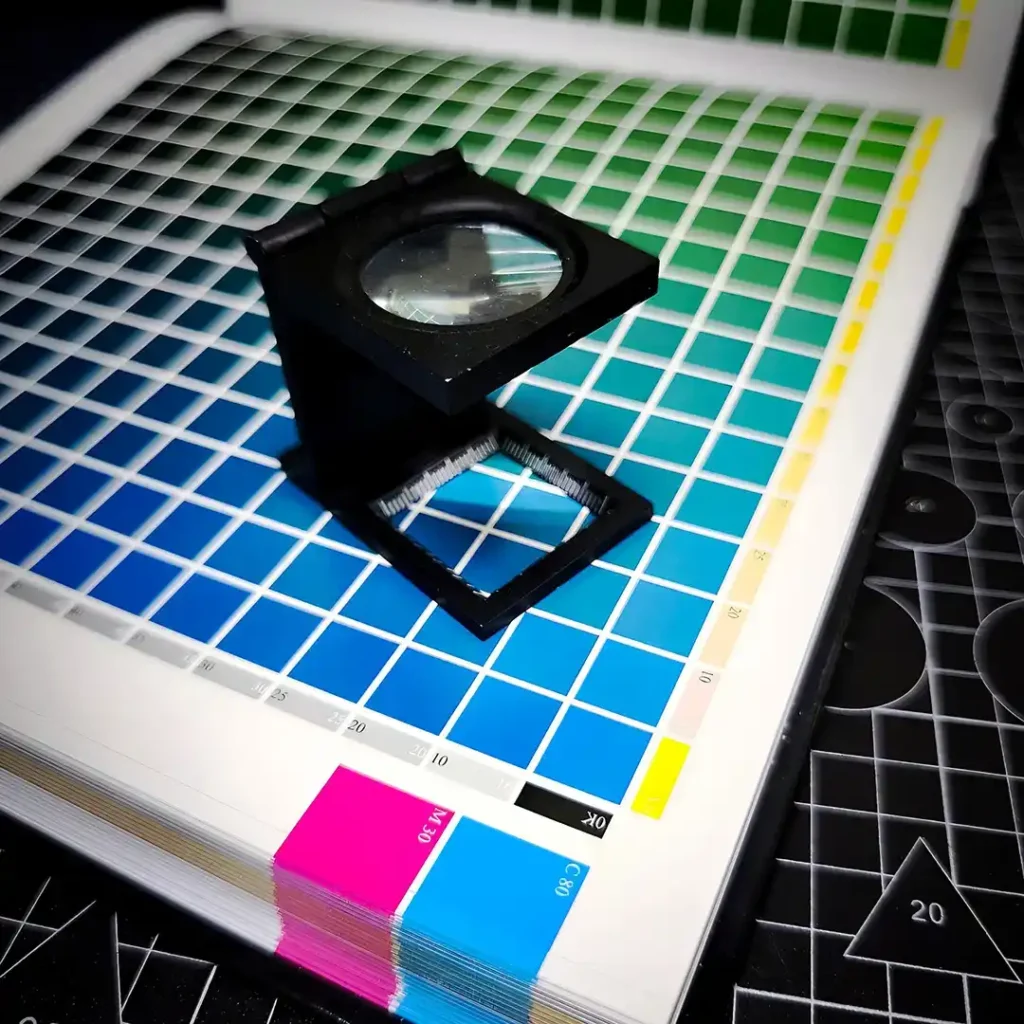

Color Management System (CMS)

We stay at the forefront of innovation by applying the most advanced color management systems to ensure unmatched consistency and accuracy in every print. Our advanced technology also allows us to precisely match colors to your specifications, maintaining perfect color fidelity across all packaging materials. This commitment to cutting-edge solutions guarantees that your packaging not only looks great but also represents your brand with flawless color precision, every time.

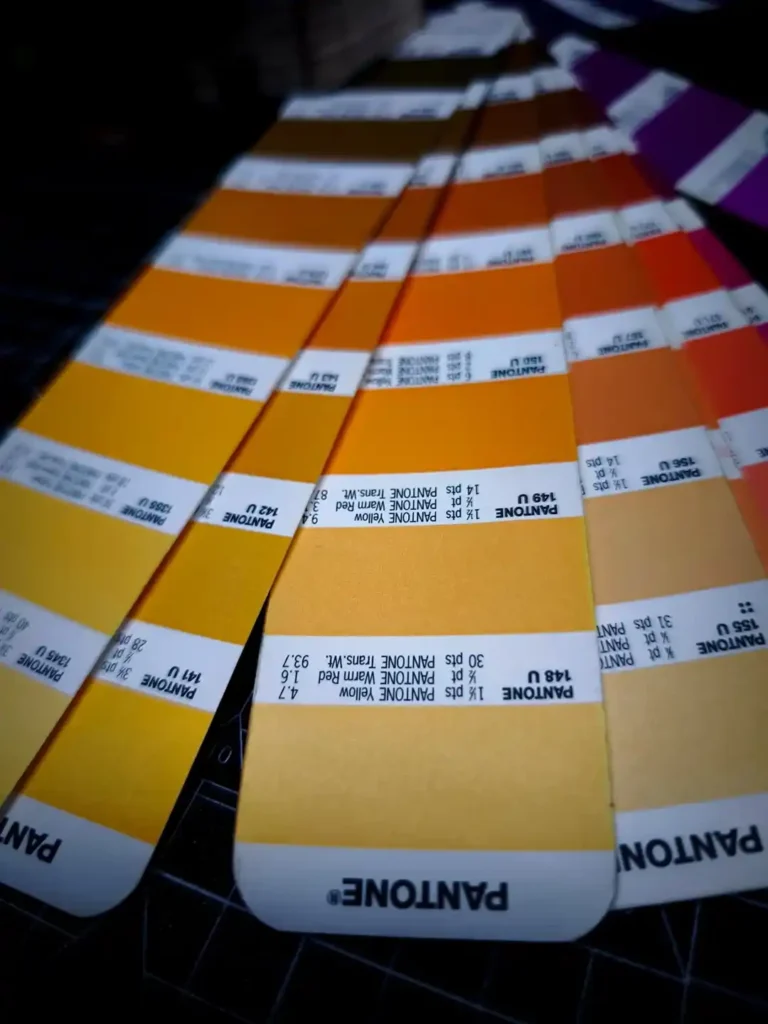

Pantone Matching System (PMS)

We leverage the industry-leading Pantone Matching System (PMS) to guarantee precise and consistent color reproduction across all our packaging solutions. This advanced system allows us to match colors to your exact specifications, ensuring that your packaging perfectly reflects your brand identity, no matter the print run. By using Pantone, we eliminate color variations and achieve superior consistency, so every package—whether large or small—maintains the same vibrant, accurate colors that your brand demands.

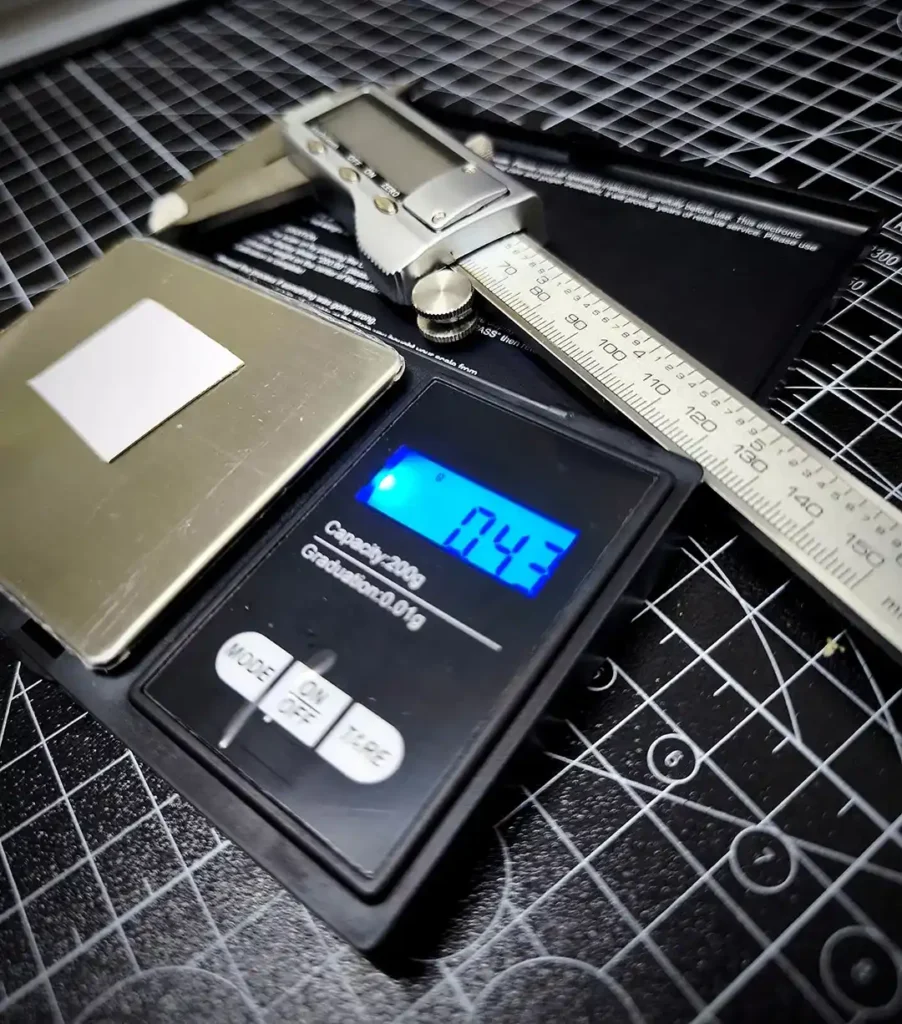

Evaluating Paper Grammage and Thickness

We evaluate paper grammage and thickness with precision tools before mass production, ensuring the correct material is used. By this measuring, we make sure the materials used meet the required standards for durability and quality. This careful evaluation guarantees that your packaging stands the test of time, offering superior strength and performance.

PHASE 3:

Post-Production

QC Department

Inspection

Our professional Quality Control (QC) department ensures that every packaging undergoes rigorous inspection, whether fully or partially, based on your specific requirements. Our skilled team meticulously checks every detail, from color accuracy to material quality, ensuring that all packaging meets the highest standards of excellence. Whether you require a full inspection for every batch or a targeted assessment, we guarantee that every product delivers on quality and consistency.